Bottom Pull Facial Tissue Paper Production Line

Product Description: Bottom Pull Facial Tissue Paper Production Line

Product Description

Product Description: Bottom Pull Facial Tissue Paper Production Line

For more information, please visit our website.

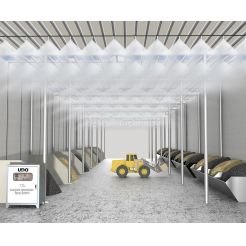

Introducing our state-of-the-art Bottom Pull Facial Tissue Paper Production Line, designed specifically for industrial manufacturers looking to enhance their tissue paper production capabilities. This highly efficient and versatile line streamlines the production of facial tissue paper, ensuring high-quality output while reducing labor costs and material waste.

Key Features:

Material: Our production line utilizes high-quality, eco-friendly raw materials, ensuring softness, durability, and skin-friendliness for end-users. The use of premium pulp materials guarantees that the produced tissues are both strong and gentle.

Size: The production line is compact yet efficient, with a total length of approximately 15 meters and a width of 3 meters. It is designed to fit into various production layouts while maintaining a high output capacity of up to 3000 boxes per day, depending on the operational speed and tissue dimensions.

Technology: Incorporating advanced automation technologies, the Bottom Pull Facial Tissue Paper Production Line features AI-assisted monitoring systems that optimize performance and reduce downtime. This intelligent integration allows for quick adjustments based on real-time data, ensuring consistent quality and efficiency throughout the production process.

Performance: Designed for high-speed operation, this production line achieves speeds of up to 300 meters per minute. With an output capacity that meets the demands of large-scale converters and suppliers, it significantly boosts productivity while maintaining precise control over the end product quality.

You will get efficient and thoughtful service from Soontrue.

How This Product Solves Problems:

The Bottom Pull Facial Tissue Paper Production Line addresses common challenges faced by manufacturers in the tissue paper industry:

Increased Efficiency: Automating the production process minimizes labor costs and maximizes output, allowing businesses to scale up their operations seamlessly.

Consistent Quality: The integration of AI technology ensures that every batch of tissue paper meets stringent quality standards, reducing waste and enhancing customer satisfaction.

Eco-Friendly Production: Using sustainable materials not only meets consumer demand for environmentally responsible products but also positions your brand as a forward-thinking industry leader.

Upgrade your manufacturing capabilities and meet the growing market demand for high-quality facial tissue papers with our Bottom Pull Facial Tissue Paper Production Line. Boost your productivity, improve product consistency, and elevate your business to the next level!

Related Products:Bottom Pull Facial Tissue Paper Production Line