centrifugal chiller vs screw chiller

Discover the superior energy efficiency and reliability of our Centrifugal and Screw Chillers, engineered for various commercial and industrial applications

Product Description

Product Description: Centrifugal Chiller vs Screw Chiller

Introduction

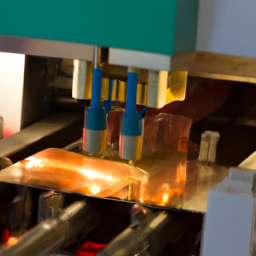

Discover the superior energy efficiency and reliability of our Centrifugal and Screw Chillers, engineered for various commercial and industrial applications. These chillers are essential for temperature control in large-scale operations, ensuring optimal climate conditions in facilities such as data centers, manufacturing plants, and commercial buildings. With state-of-the-art technology and premium materials, our chillers maximize performance, promoting cost savings and sustainable practices.

Unique Features

- Advanced Design: Both centrifugal and screw chillers are designed for high efficiency and durability, suited for diverse environments.

- User-Friendly Control: Equipped with intuitive interfaces for easy operation and monitoring.

- Scalability: Ideal for projects of any size, easily adapting to your specific cooling requirements.

Specifications:

Materials:

- Type: High-quality stainless steel and corrosion-resistant alloys ensure longevity and minimal maintenance.

- Durability: Built to withstand extreme conditions with enhanced resistance to wear and tear.

Dimensions:

- Size: Compact designs available, tailored to fit various spaces.

- Weight: Lightweight models streamline installation while robust units deliver reliable performance.

- Capacity: Offers models ranging from 100TR to 1,200TR, catering to any scale of operation.

Technology:

- AI Integration: Features smart monitoring and predictive maintenance capabilities to optimize operational efficiency.

- Energy Management System: Real-time data analytics for informed decision-making and enhanced energy conservation.

Performance:

- Efficiency: With industry-leading EER (Energy Efficiency Ratio) and COP (Coefficient of Performance) ratings, our chillers significantly reduce energy consumption.

- Speed: Rapid cooling response time to meet fluctuating demand seamlessly.

- Capacity: High cooling capacities allow for continuous operations without interruption.

Problem Solving & User Improvement

Our Centrifugal and Screw Chillers are designed to address the critical issues of energy wastage and system unreliability. By implementing advanced technology and high-quality materials, these chillers not only reduce operational costs but also contribute to a more sustainable environment. Users will benefit from improved comfort levels, reduced equipment failure incidents, and enhanced overall HVAC system performance, ultimately leading to increased productivity and peace of mind.

Conclusion

Choose our Centrifugal or Screw Chillers for a reliable, efficient, and high-performing cooling solution tailored to your business needs. Experience the difference in quality and innovation that sets us apart in the HVAC industry.

Related Products:centrifugal chiller vs screw chiller, difference between screw chiller and centrifugal chiller