induction heating solutions for pipe industry

Transform your pipe manufacturing process with our cutting-edge Induction Heating Solutions

Product Description

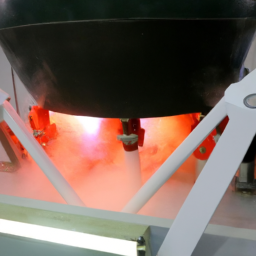

Induction Heating Solutions for the Pipe Industry

Transform your pipe manufacturing process with our cutting-edge Induction Heating Solutions. Designed specifically for the demands of the pipe industry, our advanced systems deliver precise, efficient, and reliable heating for a wide range of applications, ensuring that your operations are not only effective but also cost-efficient.

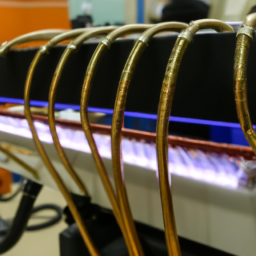

Key Specifications:

- Frequency Range: Customizable from 1 kHz to 100 kHz, ensuring optimal efficiency for various pipe materials and diameters.

- Power Output: Available models range from 10 kW to 200 kW, allowing for rapid heating and improved production times.

- Heating Capacity: Capable of uniformly heating pipes up to 12 inches in diameter, ensuring thorough treatment without hot spots.

- Control System: Equipped with an intuitive digital control panel, featuring real-time monitoring for precise temperature control and adjustment.

- Cooling System: Built-in cooling technology to maintain system longevity and ensure safe operation under continuous use.

Major Advantages:

- Energy Efficiency: Our induction heating solutions use significantly less energy compared to traditional heating methods, reducing operational costs.

- Speed & Precision: Achieve consistent heating results in a fraction of the time, boosting your throughput and minimizing downtime.

- Environmentally Friendly: The induction process produces fewer emissions, aligning with modern sustainability initiatives.

- Enhanced Quality: Directly heats the pipe surface without affecting the surrounding materials, resulting in superior product quality and reliability.

- Versatility: Suitable for various heating applications including pre-heating, bending, welding, and heat treatment of pipes and tubes.

Key Applications:

- Welding Preparation: Perfectly pre-heat pipes for welding, ensuring optimal fusion and structural integrity.

- Bending Processes: Efficiently soften metal prior to bending, allowing for cleaner and more precise bends.

- Heat Treatment: Ideal for normalizing, annealing, or hardening treatments which enhance material properties.

- Surface Treatment: Enhances surface quality and wear resistance through controlled heating processes.

Why Choose Us?

Our induction heating solutions stand out due to their unmatched reliability and performance. With years of industry experience, we understand the unique challenges faced by pipe manufacturers. Our systems are not just machines; they are investments that drive growth, quality, and sustainability in your operations.

Fulfilling your heating needs with precision, scalability, and efficiency, our induction heating solutions empower pipe manufacturers to stay ahead of the competition. Whether you are looking to upgrade your current heating technology or establish a new production line, our team of experts is ready to tailor a solution that meets your specific requirements.

Get Started Today!

Join the ever-growing community of satisfied customers who have optimized their heating processes with our technology. Contact us now to schedule a consultation, request a demo, or receive a detailed quote. Elevate your production capabilities with our state-of-the-art Induction Heating Solutions for the pipe industry — because quality starts with the right heating technology!

Related Products:induction heating solutions for pipe industry, induction bending machine